OFAS HL Series Desiccant Medium Flow Compressed Air Dryers

Combining sophisticated OIL-X fi ltration technology with an optimised

drying system, the OFAS is designed to deliver consistent high

performance over an extended period. Air quality is third party

validated to ISO 7183 and ISO 8573-1 and also offers class 0 for total oil.

So you can be completely confi dent of your compressed air quality.

Medium flow compressed air treatment systems providing pressure dew points of -70°C, -40°C or -20°C at flow rates up to 300 m³/hr @ 7 barg. Suitable for all industrial compressed air applications.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Compressed air contamination problems can be simply avoided by installing a Parker Zander OFAS HL Oil Free Air System fitted (including OIL-X filtration). The fully integrated heatless compressed air dryer and filtration packages are suitable for use with any compressor type and can be installed in the compressor room or at point of use.

Fitted with a third adsorbent column for oil vapor removal, Parker Zander’s OFAS HL Clean Dry Air Systems have been third party validated by Lloyds register to provide ISO 8573-1 Class 0, with respect to total oil from both oil lubricated and oil free compressors, ensuring the highest quality air at the point of use for critical applications.

Clean, dry, oil free air improves production efficiency and reduces maintenance costs and downtime. Only OFAS HL Oil Free Air Systems can provide the highest levels of clean, dry, oil free compressed air with validated performance.

Features & Benefits of Parker Zander OFAS HL Series Air Dryers:

• Two energy saving technologies included as standard

• 5 Stages of purification

• Treatment of 8 contaminants (10 with optional WS)

• 3rd Party validated performance

• Pre/post filtration included

• HMI display screen

• Corrosion protected

• Full bore internal flow paths

• ISO8573-1 Class 0 for Total Oil at the point of use where it’s needed

• Class 0 from an oil lubricated compressor

• High quality compressed air to ISO8573-1 classifications

• 40°C / -70°C PDP also controls microbiological growth

• Improves production efficiency and reduces maintenance costs and downtime

• Dry air means zero corrosion

• Easy and flexible installation

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

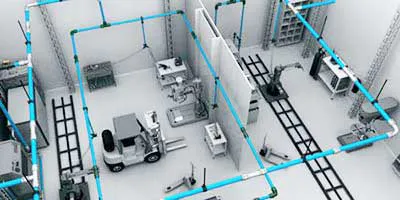

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View