Zander Air Drying, Purification and Separation Products

Zander's complete line of Compressed Air Dryers, Gas Generators, Chillers, Condensate Drains, and Compressed Air Filters

Compressed Air Dryers

Condensate Drains

Compressed Air Filters

Zander Air Dryers

Zander Heatless Desiccant Air Dryers

Compact, heatless compressed air adsorption dryers with oil vapor removal for industrial applications requiring volume flows up to 35m³/h and dew points of -25°C to -70°C.

Large flow heatless compressed air adsorption dryers with activated carbon stage for all industrial applications requiring volume flows up to 940m³/h and dew points of -25°C to -70°C.

For applications requiring high pressure compressed air or nitrogen gas up to 25 bar with volume flows of up to 600m³/h and pressure dew points down to -25/-40°C.

For applications requiring high pressure compressed air or nitrogen gas up to 50 bar with volume flows of up to 1180m³/h and pressure dew points down to -25/-40°C.

Large flow low energy modular compressed air dryers providing pressure dew points of -70°C and -40°C with flow rates up to 2040 m³/hr @ 7 barg, even greater flow rates can be achieved by multi-banking the dryers.

High pressure compressed natural gas dryer. Dries the gas on the discharge (high pressure) side, making the dryer much smaller.

Small flow compressed air dryer providing pressure dew points of -70°C and -40°C with flow rates up to 41 m³/hr @ 7 barg.

Heatless compressed air dryers for applications requiring volume flows up to 940m³/h and dew points of -25°C to -70°C.

Compact, heatless compressed air dryers for applications requiring volume flows up to 35m³/h @ 7 barg and dew points of -25°C to -70°C.

Small flow compressed air dryers providing pressure dew points of -70°C and -40°C with flow rates up to 34 m³/hr @ 7 barg.

For applications requiring high pressure compressed air or nitrogen gas up to 100 bar with volume flows of up to 650m³/h and pressure dew points down to -40°C.

For applications requiring high pressure compressed air or nitrogen gas up to 350 bar with volume flows of up to 1180m³/h and pressure dew points down to -40°C.

Large flow heatless compressed air dryers with available flow rates up to 6100m³/h @ 7 barg and pressure dew points of -25°C to -70°C, for industrial compressed air treatment applications.

Zander Inline Desiccant Air Dryers

Cost effective small capacity point of use compressed air dryers for a wide variety of applications.

Zander Regenerative Desiccant Air Dryers

For large flow industrial compressed air applications providing volume flows of up to 14500m³/h and pressure dew points down to -70°C, with energy savings of up to 25%.

Full stream HOC low energy compressed air dryers that utilise excess heat from oil-free compressors for regeneration, providing volume flows of up to 14500 m³/h @ 7 bar g.

Partial stream HOC low energy compressed air dryers that utilise excess heat from oil-free compressors for regeneration, providing volume flows of up to 14500 m³/h @ 7 bar g.

Condensate Drains

Automatic zero air loss condensate drains for industrial compressed air treatment applications.

Automatic zero air loss level sensing condensate drains for industrial compressed air treatment applications up to 50 barg.

Time controlled condensate drains for industrial compressed air treatment applications.

Compressed Air Filters

Activated carbon adsorbers for volume flows up to 6100 m³/h for industrial compressed air treatment applications.

Compact activated carbon adsorbers for the removal of oil vapor in industrial compressed air treatment applications. Available for volume flows up to 86 m³/h.

Activated carbon adsorbers for volume flows up to 940 m³/h for industrial compressed air treatment applications.

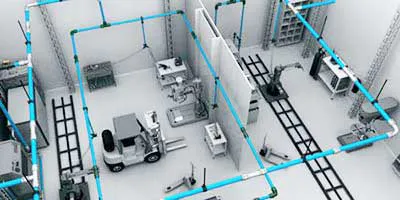

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

ecodry KA-MT 1-4 Series

ecodry KA-MT 1-4 Series ecodry KA-MT 35-95 Series

ecodry KA-MT 35-95 Series HDK 25 Series

HDK 25 Series PNEUDRI MXLE

PNEUDRI MXLE HDK-CNG

HDK-CNG PNEUDRI MIDIPLUS

PNEUDRI MIDIPLUS ecodry K-MT 35-95

ecodry K-MT 35-95 ecodry K-MT 1-4

ecodry K-MT 1-4 PNEUDRI MiDAS

PNEUDRI MiDAS HDK-MT 15/100-70/100 Series

HDK-MT 15/100-70/100 Series HDK-MT 15/350-70/350 Series

HDK-MT 15/350-70/350 Series KE-MT 120-600 SERIES

KE-MT 120-600 SERIES MDK Series

MDK Series WVM Series

WVM Series WKV series

WKV series WKT series

WKT series Ecodrain ED3000 Series

Ecodrain ED3000 Series ED4100 Series

ED4100 Series Traptronic Trap Series

Traptronic Trap Series AK 120-600 Series

AK 120-600 Series  AKM 1-8 Series

AKM 1-8 Series AKM 10-95 Series

AKM 10-95 Series